Processing technology and application of tantalum bar

Processing technology:

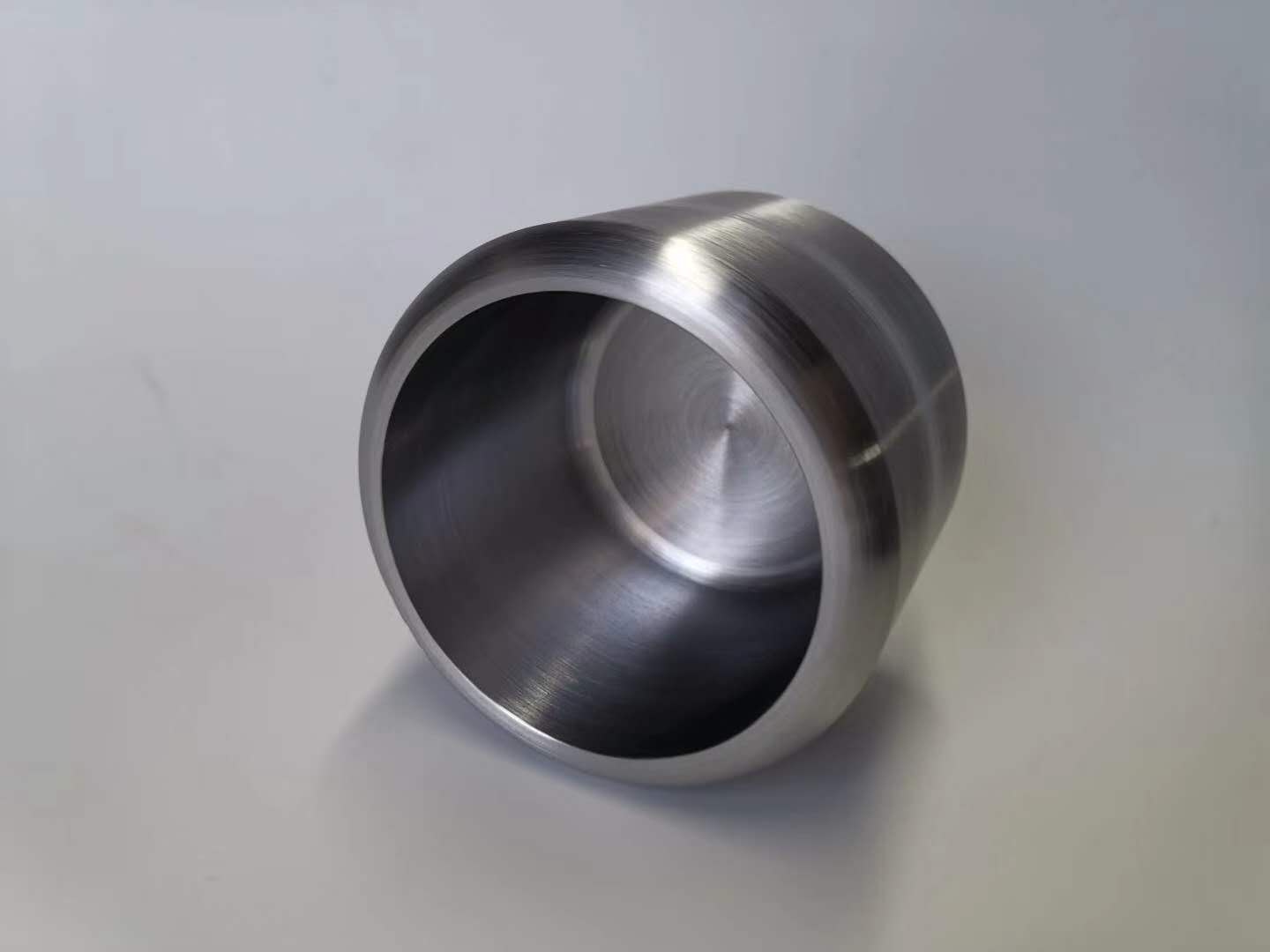

Tantalum cannot be processed in the same way as other metals. The general initial process is forging processing heat treatment, with two ways of hammering and stamping into flat slab or circular medium and small blank.

To make a bar product, it is first forged or extruded to a moderate size in the middle, with a typical yield of 70% to 90%, and then the material is annealed. Reprocessing is usually done by forging, rolling, extrusion or drawing. Wire rod is processed by a common wire drawing machine. Because tantalum material is very soft and easy to scratch, the surface problems in drawing are very serious, so the manufacturer should pay special attention to the surface condition and lubrication.

USES:

Tantalum, a metallic element, mainly found in tantalite and symbiotic with niobium. Tantalum is moderately hard and malleable and can be drawn into filaments to make thin foil. Its coefficient of thermal expansion is small. Tantalum has excellent chemical properties and extremely high corrosion resistance. Under both cold and hot conditions, hydrochloric acid, concentrated nitric acid and "aqua regia" do not react. It can be used to make evaporating vessels, etc., and can also be used as the electrode, rectifier, electrolysis, capacitance of vacuum tube. Medically used to make thin sheets or threads to repair damaged tissue.