Characteristics and properties of rare metal Molybdenum

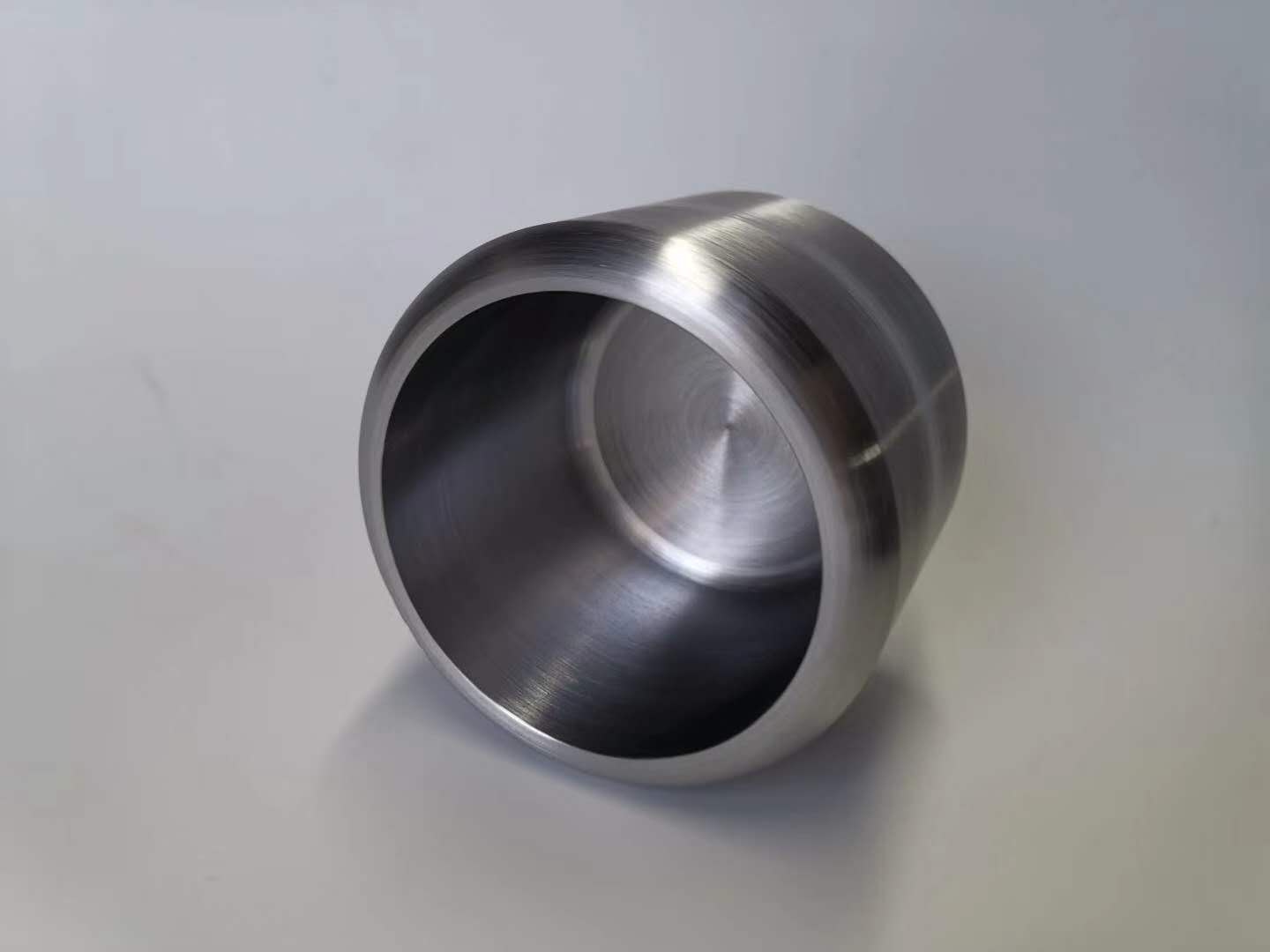

The properties of molybdenum and tungsten are very similar, with prominent boiling point and electrical conductivity, small linear thermal expansion coefficient and easier processing than tungsten. The thermal conductivity of the rare metal molybdenum [135 w/m/k] is best matched with the specific heat [0.276 kJ/kg/k], making it a natural choice for thermal shock resistance and thermal fatigue. Its melting point is 2620℃, second to tungsten and tantalum, but its density is much lower, so its specific strength (strength/density) is higher than that of tungsten and tantalum, and it is more effective in weight-critical applications. Molybdenum still has high strength at 1200℃.

The main disadvantages of molybdenum are poor oxidation resistance at high temperature (higher than 600℃ rapid oxidation) and poor ductility at room temperature. In order to make the best of it and avoid the disadvantage, coating (such as MoSi2 coating, nickel plating, chrome plating, etc.) is used to control high-temperature oxidation. The deficiency of low temperature embrittlement, which is called plastic excess, can be solved by means of alloy strengthening and carbide adding.

Tungsten (W), Rhenium (Re), tantalum (Ta), titanium (Ti) and zirconium (Zr) are common solid solution strengthening elements. Tungsten is the main solid solution strengthening element of molybdenum, and rhenium can reduce the transition temperature to 200℃. The industrial molybdenum alloys formed by them are shown in the table. The molybdenum-Lanthanum alloy made of lanthanum showed excellent creep resistance and high temperature deformation, especially at high temperature.

The above information is compiled and released by Baoji Jiritong Rare Metals Co., LTD.

下一篇:没有了