Polishing process and application of Tungsten rod

Tungsten Bar (English name: Tungsten Bar) is also called Tungsten alloy Bar. Tungsten alloy bar material has low thermal expansion coefficient, good thermal conductivity and good material properties. At high temperature, tungsten alloy bar is a material with high melting point and low thermal expansion coefficient. The addition of tungsten alloy elements improves machinability, toughness and welding. The properties of the material are built in manufacturing tungsten alloy bars to eliminate problems associated with heat treatment of other tool materials.

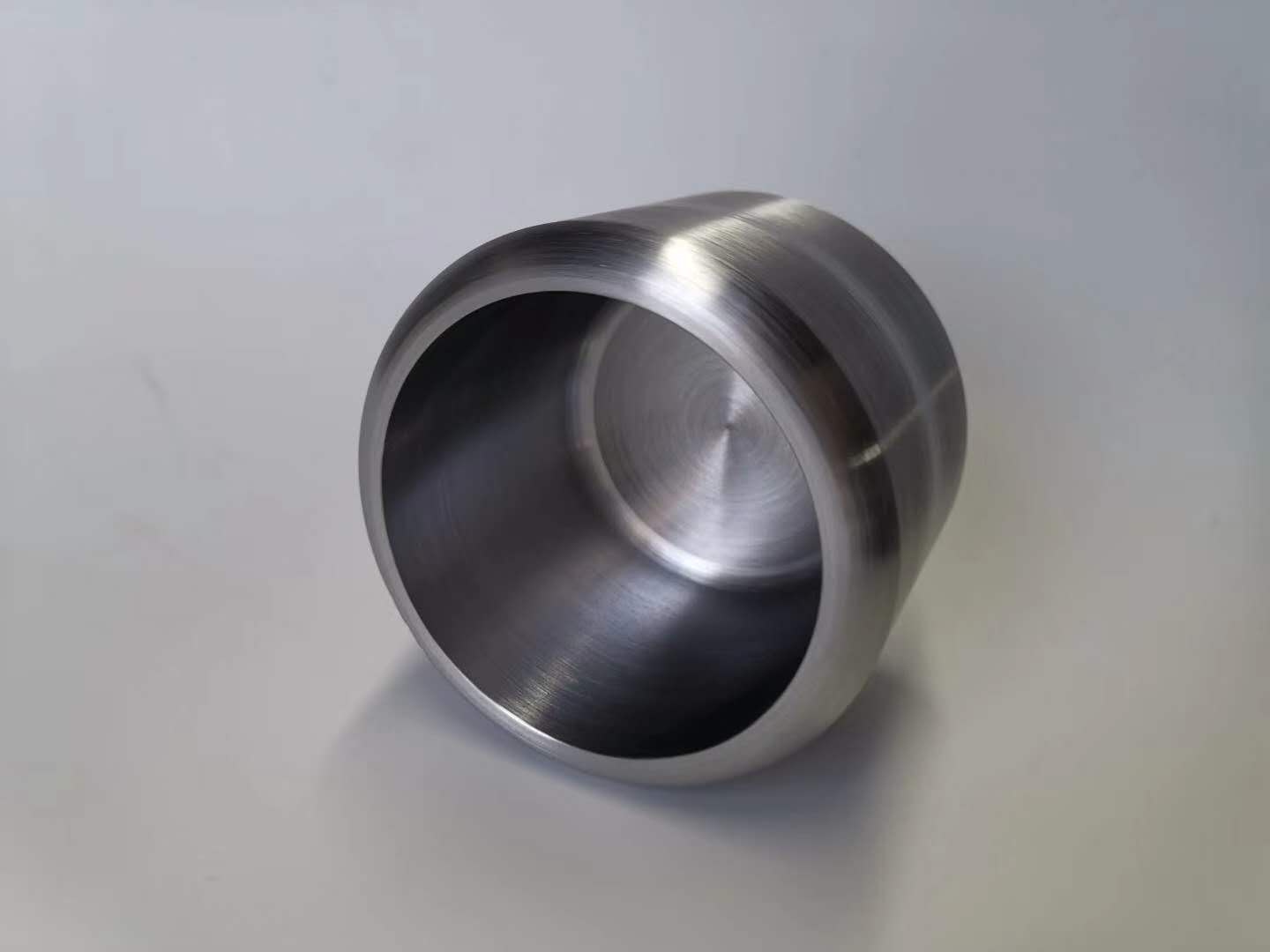

Besides physical and mechanical polishing, there are two surface polishing processes for tungsten alloy bars, which are respectively:

1. Chemical polishing; 2. Electrochemical polishing.

Application:

Tungsten bars have special properties such as low thermal expansion and good thermal conductivity, sufficient resistance to electrical resistance, and high modulus of elasticity. Therefore, tungsten bars are widely used in various fields. Mainly used in military, industrial and civil: welding electrode, glass melting, various electrodes and quartz furnace, filament, high-speed tools, auto automatic products, sputtering target. Baoji Jiritong Rare Metals Co., LTD. Can supply tungsten bars with polished surface and sintered and forged tungsten bars. Depending on the size and conditions, the diameter can range from 1 to 30 mm and the length from 500 mm.