The properties of tungsten alloy and the rolling process of tungsten plate are introduced

The tungsten content in commonly used tungsten and molybdenum alloys is 30% ~ 50% (quality). The production method of tungsten and molybdenum alloy is the same as that of molybdenum material and molybdenum alloy, that is, there are two methods of sintered powder metallurgy and smelting, which can produce rods, plates, wires or other profiles. Tungsten-molybdenum alloys containing tungsten 30% (quality) have excellent corrosion resistance to liquid zinc and are used in the manufacture of agitators, piping and container linings and other components of the zinc smelting industry. Tungsten and molybdenum alloys can be used as high-temperature components, vacuum tube filaments, parts and other high-temperature materials in rockets and missiles under corresponding high-temperature conditions due to their high temperature strength, similar properties and smaller specific gravity than tungsten.

Two elements in the same column of the periodic table. They show the same properties. Two elements with an average concentration of 1.5 parts per million in the crust. Molybdenum is an essential nutrient for plants and animals. In high concentrations, molybdenum can cause poisoning, sometimes from alkaline ash leachate cases. Tungsten is an important strategic metal and is used in a variety of industrial applications. It is usually mined from scheelite, powder CaWO4, light channel wolframite (iron, manganese) WO4. Tungsten is released into the environment, for example through its winter tires and ammunition. In general, tungsten's environmental behavior is not well known.

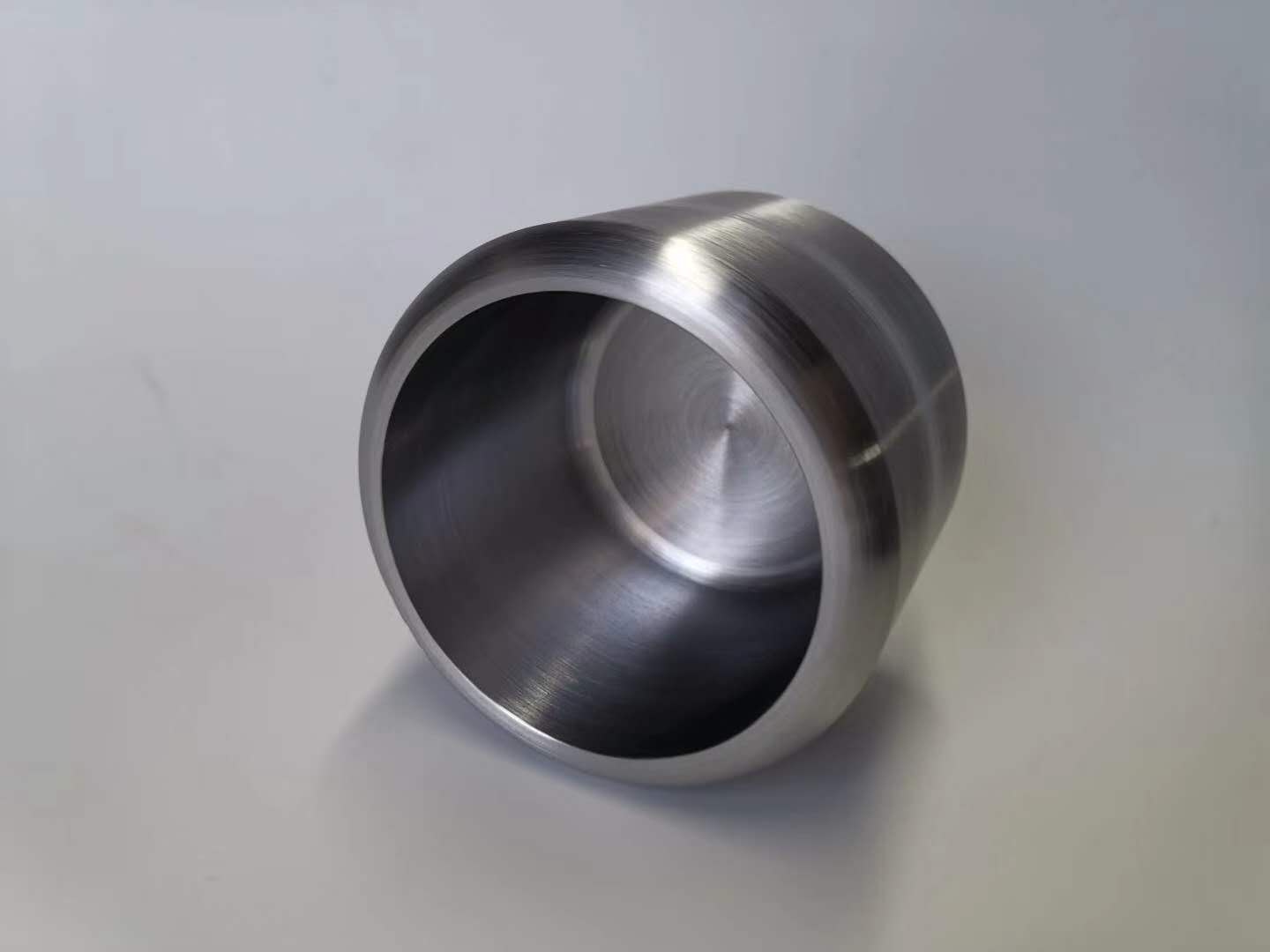

For tungsten plate rolling can be divided into hot rolling, warm rolling and cold rolling. Due to the large deformation resistance of tungsten, ordinary roll can not fully meet the requirements of tungsten sheet rolling, so special roll should be used. When rolling, the roll to preheat, according to different rolling conditions, preheat temperature is 100 ~ 350℃. The relative density of billet (the ratio of actual density to theoretical density) is greater than 90%, and the processing performance of billet is good at 92 ~ 94%. The blank opening temperature of hot rolling is between 1350 ℃ and 1500℃. A hot rolled plate with a thickness of 8 mm and starting temperature of 1200℃ can be rolled at a temperature of 0.5 mm.

Tungsten plate steel gray or silver white, high hardness, high melting point, not by air erosion at room temperature; It is mainly used for manufacturing filament and high speed cutting alloy steel, super hard die, also used in optical and chemical instruments. China is the world's largest tungsten depositor.

A metallic element, silver-white crystalline, hard and brittle, with a high melting point, that can be made into very fine wire and special alloy steel: tungsten. Tungsten iron. Tungsten steel. Tungsten ore (selected tungsten ore).

Tungsten is not only a nonferrous metal, but also an important strategic metal. Tungsten ore was called "heavy stone" in ancient times. In 1781, Swedish chemist Carl Wilhelm Scheele discovered scheelite and extracted a new element acid-tungstenic acid. In 1783, Wolframite was discovered by The Spaniard DE Preya and also extracted tungstenic acid from wolframite. In the same year, tungsten powder was obtained by reducing tungsten trioxide with carbon, and the element was named. Tungsten is found in 0.001% of the earth's crust. Twenty kinds of tungsten - bearing minerals have been found. Tungsten deposits are generally formed with the activity of granitic magma. Tungsten is a silver-white glossy metal with a very high melting point and high hardness. Tungsten is an element with a very high melting point.