Classification of rare metals and their USES?

A rare metal is usually a metal that is found in small or dispersed quantities in nature.

They are difficult to be extracted from raw materials and are relatively late in industrial preparation and application. But in the modern industry has a wide range of applications, such as used in the manufacture of special steel, super hard alloy and high alloy, in the electrical industry, chemical industry, ceramic industry, atomic energy industry and rocket technology and so on.

The names of rare metals are relatively relative. With the extensive research of rare metals, the discovery of new sources and new extraction methods, and the expansion of their application, the boundary between rare metals and other metals will gradually disappear. For example, some rare metals have more content in the earth's crust than copper, mercury, cadmium and other metals.

"Classification"

According to the physical and chemical properties, occurrence state, production process and other characteristics of various elements, rare metals are generally technically divided into the following five categories:

Rare light metals include lithium, rubidium, cesium and beryllium. Small specific gravity, strong chemical activity.

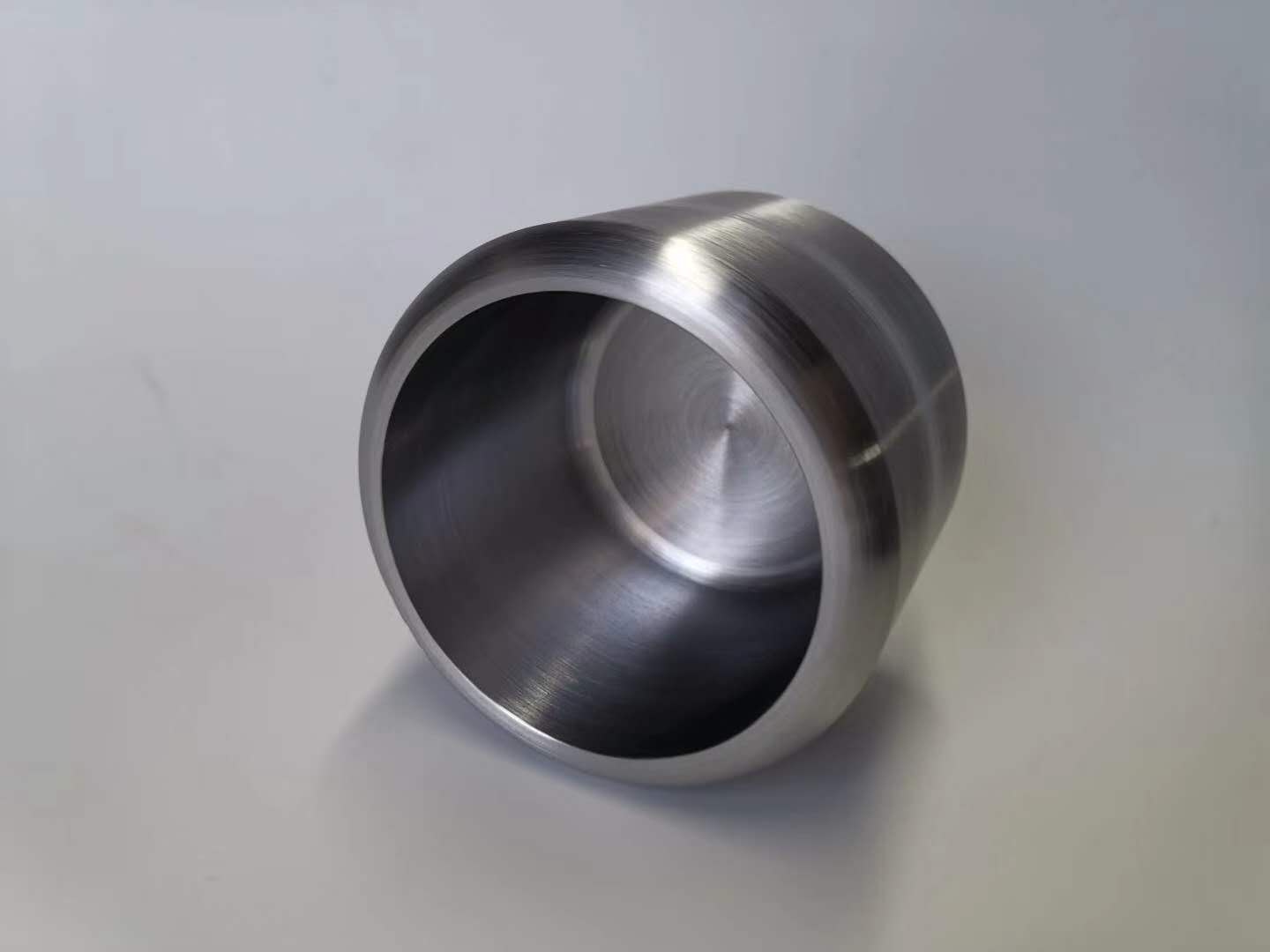

Rare refractory metals include titanium, zirconium, hafnium, vanadium, niobium, tantalum, molybdenum and tungsten. Higher melting point, with carbon, nitrogen, silicon, boron and other compounds formed by the melting point is also higher.

Rare dispersed metals are referred to as dispersed metals, including gallium, indium, thallium, germanium, rhenium, selenium, and tellurium. Most occur in minerals of other elements.

Rare earth metals are referred to as rare earth metals, including scandium, yttrium and lanthanide elements. They have very similar chemical properties and are associated with each other in minerals.

Rare radioactive metals include the naturally occurring francium, radium, polonium, and actinium metals, along with thorium, magnesium, uranium, and artificially produced technetium, promethium, other elements of the actinide family, and elements 104 to 107.

The above classification is not very strict. Some rare metals may be included in one group or another. Rhenium, for example, can be classified as either a rare or refractory metal.

[usage]

Indium: China has the largest reserves in the world. It accounts for 80 per cent of global supply. Mainly used in flat panel display, alloy, semiconductor data transmission, aerospace products manufacturing. Main associated in lead-zinc ore, China's primary indium production in 2005 only 410 tons. Indium, which is a companion metal, is just a zinc concentrate whose contents are calculated in parts per million (PPM), so small that they cannot be regenerated.

Tungsten: China's world's largest reserves. It accounts for 85 per cent of global supply. Mainly used in cemented carbide, special steel and other products, and widely used in the national defense industry, aerospace, information industry, known as the "teeth of industry." Tungsten can withstand high, so tungsten alloy is widely used in the machinery, weapons industry. Tungsten is used in the firing tubes of guns and guns, for example. The bullets used in military armour-piercing rounds are made of high-density alloy steel, tungsten carbide and other materials that are much harder than tank armor. The mechanical properties of tungsten alloys are similar to those of depleted uranium, and its disadvantages are its advantages. Tungsten is not radioactive and its chemical properties are very stable. It does not oxidize even above 1000℃, and its hardness does not decrease significantly. This is good for high metal jets against armor breaking. The hardness of tungsten is very high, mainly used in the alloy of iron and steel. After adding tungsten, the hardness of steel will be greatly improved. In the field of metal processing, the tool material high-speed steel is the alloy containing tungsten. If a country does not have tungsten, under the current technical conditions of the metal processing capacity will appear a great loss, directly leading to the paralysis of the mechanical industry, so called strategic metal. It is also necessary to use tungsten as a filament in lighting.

Molybdenum: China has the second largest reserves in the world. It accounts for 24 per cent of global supply. Used for refining various kinds of alloy steel, stainless steel, heat resistant steel, super alloy, widely used in the military industry, known as "war metal".

Rare earth: China has the largest reserves in the world. Supply accounts for more than 80 per cent of the global total. Used for manufacturing composite materials, magnesium, aluminum, titanium and other alloy materials, is figuratively compared to "industrial MONosodium glutamate.

Germanium: The world's largest reserves. It produces 50% of the world's output. It is mainly used in the production of night vision instrument, thermal imager, petroleum product catalyst and solar cell, and is widely used in the field of optical fiber communication.

In addition, tantalum, strontium, antimony, cadmium, iridium, bismuth, rhodium, titanium, nickel, zirconium, chromium, cobalt and so on as well as nickel chromium, nickel chromium silicon, nickel aluminum, titanium aluminum, iron nickel and so on, many of these are strategic metals in Europe and also have a wide range of USES in national defense construction. Tantalum, for example, is not only useful in artillery, but also a necessary material for future space exploration. Scientists are still studying its unique physical and chemical properties, and the special USES of tantalum alloy are still being researched and developed.

Smelting technology The amount of rare metals in the earth's crust is not always small. For example, the contents of titanium, zirconium and vanadium in the earth's crust are higher than the common non-ferrous metals nickel, copper, zinc, cobalt, lead and tin. Due to the occurrence and dispersion of rare metals, and often associated with other metals, some physical and chemical properties of special, so it is often necessary to adopt special production technology. For example, lithium, rubidium, caesium, beryllium, zirconium, hafnium, tantalum, niobium, tungsten, molybdenum, gallium, indium, thallium, germanium, rhenium, lanthanide and actinide metals are separated and extracted by organic solvent extraction method and ion exchange method. Lithium, beryllium, titanium, zirconium, hafnium, vanadium, niobium, tantalum and rare earth metals are prepared by metal thermal reduction and molten salt electrolysis. Titanium, zirconium, hafnium, tantalum, niobium and rare earth metals are extracted, separated or reduced by metallurgy chloride. High purity titanium, zirconium, hafnium, vanadium, uranium and thorium were prepared by iodide thermal decomposition. A series of metallurgical technologies such as vacuum sintering, arc melting, electron beam melting and plasma melting have been widely used to refine rare metals, especially rare refractory metals. Regional melting technology has been an effective means to produce high purity rare and refractory metals.

With the progress of science and technology, the development of metallurgical technology, equipment and analysis and detection technology, and the expansion of the production scale of rare metals, the purity of rare metals is constantly improved, the performance is constantly improved, and the varieties are constantly increased, which promotes the expansion of the application field of rare metals. Some metallurgical processes of rare metals such as organic solvent extraction technology and chlorination technology have been gradually extended to the whole field of non-ferrous metals metallurgy. China is rich in rare metal resources, such as tungsten, titanium, rare earth, vanadium, zirconium, tantalum, niobium, lithium, beryllium and other proved reserves, ranking first in the world. China is gradually establishing an industrial system of rare metals.

上一篇:没有了