Application and development of molybdenum

Molybdenum reserves in the earth is small, its content is only 0.001% of the weight of the earth's crust, the total reserves of molybdenum about 15 million tons, mainly distributed in the United States, China, Chile, Russia, Canada and other countries. China's proven reserves of molybdenum are 1.72 million tons, and the basic reserves are 3.43 million tons, second only to the United States and second in the world. Molybdenum mines are concentrated in Shaanxi, Henan, Jilin and Liaoning provinces. There are six super large molybdenum mines with metal reserves of more than 500,000 tons in the world, including Henan Luanchuan, Jilin Daheishan and Shaanxi Jinduicheng.

The abundant molybdenum resources provide a very favorable condition and a solid foundation for developing the smelting and processing of molybdenum and promoting the application of molybdenum in China. Molybdenum, like tungsten, is an refractory rare metal. The melting point of molybdenum is 2620℃. Due to the strong binding force between atoms, it has high strength at room temperature and high temperature. It has small expansion coefficient, high conductivity and good thermal conductivity. At room temperature, it does not react with hydrochloric acid, hydrofluoric acid and alkali solution. It is only soluble in nitric acid, aqua aqua or concentrated sulfuric acid. It is also quite stable for most liquid metals, non-metallic slag and molten glass.

Therefore, molybdenum and its alloys have a wide range of applications and good prospects in metallurgy, agriculture, electrical, chemical, environmental protection, aerospace and other important sectors, and become an important raw material and irreplaceable strategic substances in the national economy.

The mining and application of molybdenum in China

In recent years, the mining, smelting and processing of molybdenum in China have developed rapidly.

According to information, the reality of our country in 2001 72000 tons of production of molybdenum concentrate, molybdenum oxide 33000 tons, 7600 tons of molybdenum iron, all kinds of 9500 tons of ammonium molybdate, molybdenum bars, 1183 tons, 1200 tons of mo slab, molybdenum plate 150 tons, 40 tons, molybdenum discs about 50 tons of molybdenum immediate and other special products, electric light source industry and machinery processing molybdenum wire of 3.15 billion meters, and lubricants, catalysts, pigments and other chemical products hundreds of tons.

Moreover, China holds a pivotal position in the world molybdenum market. According to customs statistics, China exported 70,274 tons of molybdenum ores, molybdate, ferro molybdenum and other molybdenum products in 2001, earning foreign exchange of 262 million US dollars.

The consumption forms of molybdenum are mainly industrial molybdenum trioxide, accounting for about 70%, ferromolybdenum accounting for about 20%, molybdenum and molybdenum chemicals accounting for 5% respectively. Its application field and allocation proportion is as follows: about steel consumption accounted for about 80% (about 43% of alloy steel, stainless steel is about 23%, tool steel and high speed steel by about 8%, cast iron and roll about 6%), chemical products accounted for about 10%, metal molybdenum products consumption accounts for about 6%, high temperature and high strength alloys and special alloys accounts for about 3%, other molybdenum products is about 1%. It can be seen from above that the development of iron and steel industry plays a decisive role in the consumption of molybdenum, but with the development of science and technology, the application of molybdenum in high-tech and other fields will continue to expand and develop.

Iron and steel industry

According to the statistics of molybdenum consumption around the world, the application of molybdenum in iron and steel industry still occupies the most important position. As an alloying element of steel, molybdenum can improve steel strength, especially high temperature strength and toughness. To improve the corrosion resistance of steel in acid base solution and liquid metal; To improve the wear resistance and hardenability, weldability and heat resistance of steel. Molybdenum is a good carbide forming element. It is not oxidized in the process of steelmaking. It can be used alone or in conjunction with other alloying elements. The molybdenum consumption of special steel has been increasing regularly. At present, the molybdenum consumption of special steel has reached 0.201 kg.

Molybdenum and chromium, nickel, manganese and silicon can be manufactured in different types of stainless steel, tool steel, high speed steel and alloy steel. The stainless steel made has good corrosion resistance and can be used in corrosion resistant steel pipes for petroleum exploitation. A stainless steel with molybdenum added about 6% can also replace titanium for seawater desalination plants, ocean-going ships and offshore oil and gas exploitation pipelines. This type of stainless steel can also be used in car shells, sewage treatment equipment and so on. Molybdenum tool steel is twice as efficient as tungsten tool steel, has good performance, low cost and light weight. Molybdenum series high speed steel has the advantages of carbide non-uniformity, wear resistance, good toughness, high temperature plasticity and so on. Molybdenum alloy steel can be used in the construction of machine tools, industrial vehicles and earth-moving equipment. Molybdenum alloy steel with fine pearlite microstructure is an important steel in railway and bridge construction. As an alloy additive of iron, molybdenum contributes to the formation of a complete pearlite matrix, improves the strength and toughness of cast iron, enhances the uniformity of microstructure of large castings, and enhances the quenchability of heat-treated castings. Molybdenum gray cast iron has good wear resistance and can be used as brake wheel and brake pad for heavy vehicles.

Electronic electrical

Molybdenum has good conductivity and high temperature properties, especially close to the thermal expansion coefficient of glass, and is widely used in the manufacture of spiral filament core wire, lead wire, hook, bracket, side rod and other components, as gate and anode support material in vacuum tube. Molybdenum is used as a metal oxide semiconductor gate in vLSI. The ultra-thin seamless molybdenum tube (about 15 m) can be used as an anodic support for the picture tube of a high-definition television set with 1,125 image scanning lines, which is twice as large as that of a conventional television set. Molybdenum wafer can also be used as power transistor heat shield and silicon rectifier substrate and heat sink. In addition to the use of pure molybdenum in modern electronic industry, Mo-RE alloy can be used as the structural material for electron tubes and special bulbs. Mo-50re and TZM alloy can also be used as thermitic cathode structural elements in high-power microwave tubes and millimeter-wave tubes. The operating temperature can reach 1200℃, and the current density can reach 10 amperes/cm 2. The recrystallization temperature of pure molybdenum wire as the outlet line is low, and it is easy to embrittlement at high temperature, which affects the service life. In recent years, some people have developed to add Si, K, C and other elements to improve the recrystallization temperature and produce "high-temperature molybdenum wire".

The addition of rare earth elements yttrium, cerium and lanthanum in the process of molybdenum oxide production can improve recrystallization temperature more effectively and overcome the problem of high-temperature embrittlement of materials. Molybdenum wire containing 0.1-0.3% zirconium and 0.1% scandium is nitrified at 1200℃ to diffuse scandium into the whole alloy. The tensile strength of this molybdenum wire can reach 1400 million Pascals at 20℃.

With the rapid development of die industry, edM technology has been widely applied. Molybdenum wire is an ideal electrode wire for EDM wire-cutting machine tools, which can cut all kinds of steel and hard alloy and process parts with extremely complex shapes. Its discharge machining is stable and can effectively improve the precision of the die.

The above are the two most widely used molybdenum wire, the development of light bulb manufacturing industry and the rise of mold manufacturing industry, so that the production and consumption of molybdenum wire by leaps and leaps. According to the statistics of China Lighting Association, in 2001, the national production of molybdenum wire reached 3.15 billion meters, the actual output was estimated to reach 4 billion meters, and the consumption of nearly 800 tons of molybdenum strip was very considerable. The production of molybdenum wire for wire cutting exceeds 2 billion meters, accounting for more than half of the total molybdenum wire, and its market development prospect is very optimistic.

Tungsten-copper alloy is widely used in edM cutting tool electrodes. However, in recent years, molybdenum is used instead of tungsten as the electrode. The results show that the corrosion resistance of tungsten and molybdenum based electrodes varies with the content of copper (≤50% weight). In the presence of heating pulse and mechanical load pulse, the corrosion resistance mainly depends on the embrittlement process. The extension-brittle transition temperature of molybdenum is lower than that of tungsten, so the brittleness is small and the corrosion resistance is strong. Molybdenum-copper and molybdenum-Silver pseudoalloys have ablative resistance and good electrical conductivity, and can be used as contacts for air switches, high pressure switches and contactors. The molybdenum-copper composite film is embedded with a large number of discrete molybdenum particles on the continuous copper body. It has uniform microstructure and good heat conduction and electrical conductivity through the thickness. It can be used as metal core in multilayer circuit board.

Recently, molybdenum trioxide, a material that changes color when exposed to strong light and can be easily reduced, has been developed for use in optical storage components of electronic computers and for repeated use as a copy material.

Agricultural fertilizer

Molybdenum is one of the essential "trace elements" in plants, accounting for about 0.5 PPM of the plant dry matter, which is indispensable and irreplaceable. In recent years, ammonium molybdate has been widely used as micronutrient fertilizer, which can significantly improve the quality and yield of legumes, herbage and other crops. This is mainly because molybdenum promotes the fixation of nitrogen in the air by rhizobia and other nitrogen-fixing organisms and further converts nitrogen into proteins needed by plants. Molybdenum also promotes the uptake of phosphorus and its role in plants. Molybdenum can also accelerate the formation and transformation of sugars in plants, improve the content and stability of chlorophyll and the content of vitamin C. Not only that, molybdenum can also improve the drought and cold resistance and disease resistance of plants.

The application of molybdenum fertilizer is characterized by low amount, high effect and low cost, which is an important measure to improve agricultural harvest, especially soybean harvest. The wide application of molybdenum in agriculture has opened up a new way for the comprehensive utilization of waste water, waste residue and low grade ore of molybdenum production plants in China.

Car painting

The melting point of molybdenum is as high as 2620℃, and it has good high-temperature performance and corrosion resistance. Molybdenum has strong binding force with steel, so it is the main thermal spraying material in the production of automobile parts. Auto parts general high-speed flame spraying molybdenum wire, gas mixture injection device spray gun to produce the high temperature gas combustion, a specially designed combustion chamber and gas jet mixing chamber, the molybdenum wire before completely melted, with extremely high speed coating on the surface of the workpiece, the injection of molybdenum density can reach more than 99%, bonding strength nearly 10 kg / ㎜ 2. This process effectively improves the wear resistance of the surface and provides a porous surface that can be impregnated with lubricating oil. It is widely used in the automotive industry to improve the performance of piston rings, synchronous rings, shifting forks and other worn parts, as well as to repair worn crankshafts, rollers, shafts and other mechanical parts. According to the data introduced the spraying molybdenum wire European market annual sales volume can reach 1000 tons, the United States annual consumption is also up to about 600 tons, Japan also consumes 30-40 tons of molybdenum wire every year, China's spraying molybdenum wire market capacity is less than 30 tons per year. However, with the development of China's automobile industry, the thermal spraying of automobile gears and other components will have a great development, and the sales of spraying molybdenum wire will increase greatly.

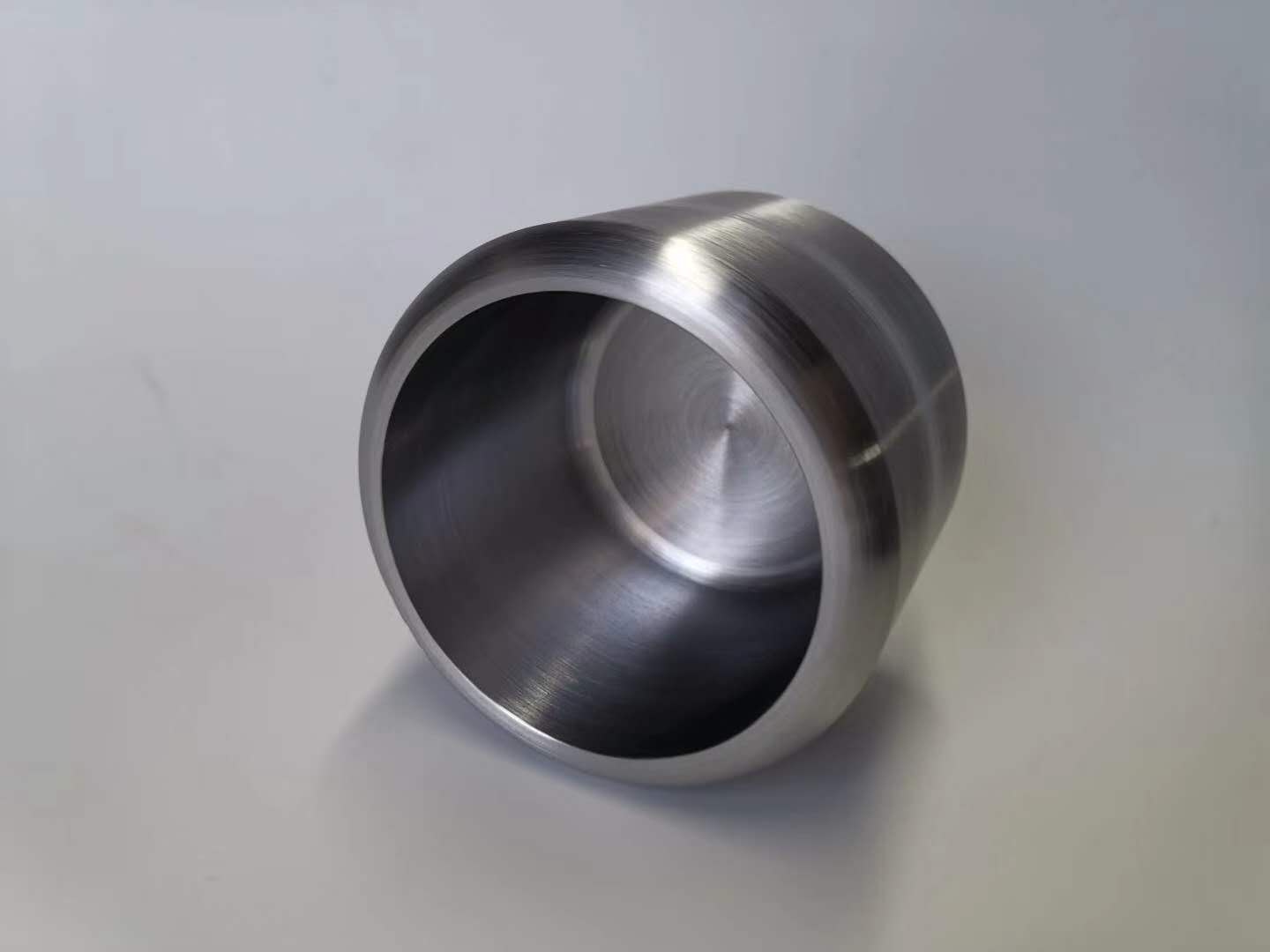

High temperature components

Because of its high purity, high temperature resistance and low steam pressure, molybdenum is often used as the heating element and structural material of high temperature furnace. In the production process of tungsten, molybdenum and hard alloy, most of the reduction furnace and sintering furnace are made by means of molybdenum wire heating, and some iron products are continuously sintered with molybdenum rods heating and discharging, and molybdenum rods heating and discharging are hung on both sides of the furnace with molybdenum hooks. This kind of furnace is generally in reducing atmosphere or non-oxidizing atmosphere, in hydrogen and ammonia decomposition molybdenum wire can be used to near the melting point, nitrogen can be used to 2000℃. When the temperature is higher than 1700℃, TZM alloy or molybdenum-Lanthanum alloy with higher recrystallization temperature and better strength can be used as heating element. Molybdenum has a very good ablative performance in molten quartz, and is used as an electrocurrent fused electrode in the glass industry. It only loses 7.8 grams per ton of glass molybdenum electrode, and its service life can be more than one year. In addition to being an electrode, molybdenum is also used as a glass melting high-temperature structural material, such as a guide tank, pipe, crucible, flow port and a stirring rod for rare earth smelting. The effect of molybdenum-substituted platinum on glass fiber drawing furnace is good and the production cost is greatly reduced. Recently developed nuclear fuel sintering furnace adopts molybdenum grid heating; 0.8mm molybdenum wire weaving into three-phase net heater; working temperature up to 1800 -- 2000℃. In addition, molybdenum and its alloy can also be used as hot isostatic pressure furnace frame, heat insulation screen, sintered and steamed coated feed boat, SmCo magnet and uranium dioxide sintering plate, thermocouple and its protective sleeve, etc.

Molybdenum silicide (MoSi2) is a widely used heating element material, which has the characteristics of high temperature oxidation resistance, excellent corrosion resistance and high melting point. Its oxidation resistance is due to the formation of an airtight glass film on the heating surface, which is not damaged by oxygen, nitrogen, carbon monoxide and sulfur dioxide. Molybdenum disilicide can be heated for two to three years at 1700 -- 2000 K. But the poor mechanical properties affect the application of molybdenum silicide, if add SiC in molybdenum silicide formed a kind of composite material, this material will be silicon carbide dispersion in the matrix of molybdenum disilicide, generate double metal compounds containing molybdenum and silicon atoms, its high temperature strength is high molybdenum disilicide monomer eight times as much, make its application demand.

Oil drilling

In the development of low-lying acidic natural gas, oil fields and undersea oil and gas fields, not only a large amount of H2S gas is produced, but also the erosion of sea water makes the vulcanization of drilling pipeline brittle and rapid corrosion. High strength stainless steel tubes containing molybdenum can effectively resist H2S gas and seawater corrosion, greatly saving steel and reducing drilling costs of oil and gas Wells.

Molybdenum is not only used for drilling pipelines in oil and gas fields, but also used in combination with drilling and nickel as catalyst for petroleum refining and pretreatment, mainly for desulfurization of petroleum, petrochemical products and liquefied coal. In the process of hydrogen treatment, sulfides react with hydrogen on the surface of catalysts, sulfur ions are removed in the form of hydrogen sulfide, and nitrogen and metal impurities in crude oil are eliminated at the same time, in order to reduce the toxicity of these impurities to other catalysts in petroleum refining, thus improving the color, smell and stability of products. After passivation, a layer of carbon remains on the surface of molybdenum catalyst. If the carbon layer is burned off, the catalyst can resume its active state and its service life can be about 1-5 years. Molybdenum plays an important role in petroleum cracking and reforming and is an ideal electron donor and carrier.

The environmental protection

People more and more clearly realize that molybdenum plays an important role in the control of environmental pollution, the large number of applications of molybdenum-containing stainless steel, greatly reduce the impact on the environment caused by rust; In addition, most of molybdenum and its compounds are non-toxic, and the use of relatively safe molybdenum to replace toxic metals is also a major contribution of molybdenum to human environmental protection. In the paint and pigment industry, molybdenum can replace toxic chromium, lead, titanium and other metals, and is a highly effective colorant. In the chemical industry can replace preservatives in chromium and flame retardant, smoke in antimony; Application of molybdenum in water treatment industry also has the potential, mainly in the open and closed cycle cooling system used for inhibiting corrosion in cooling water treatment, a litre of coolant in the open circuit cooling tower 2 to 10 mg of sodium molybdate, and closed circuit cooling water air conditioning unit per liter of up to 150 mg of sodium molybdate as automobile antifreeze and cooling systems, and the dosage of the preservative is also increasing in the cutting fluid. It is also suggested that molybdenum can improve vitrified soil, simplify the treatment of highly polluted soil and reduce soil pollution.

Aviation and nuclear industries

Molybdenum alloy with excellent heat resistance and high temperature mechanical properties, flame guide for aircraft engine and combustion chamber, the messenger of the liquid rocket engine valves and pipes, nozzle, a return to the end of the aircraft, satellites and spacecraft of the skin, wing and guide plate and protective coating materials, low thermal coefficient and good thermal performance, molybdenum under solar radiation light intense exceptionally good dimensional stability, with the metal molybdenum network satellite antenna, can maintain its complete parabolic shape, and lighter than graphite composite antenna. Cruise missile USES molybdenum coating material as turbine rotor, working at 1300℃ high temperature, rotating speed up to 40,000-60,000 RPM, has shown a good effect.

Molybdenum has a small neutron absorption cross section, good strength, good stability to nuclear fuel, good resistance to liquid metal corrosion, and can be used as a protective plate for converter armor elements in nuclear fusion reactors. Mo-re alloy can be used for air