The manufacturing process and application of tantalum wire

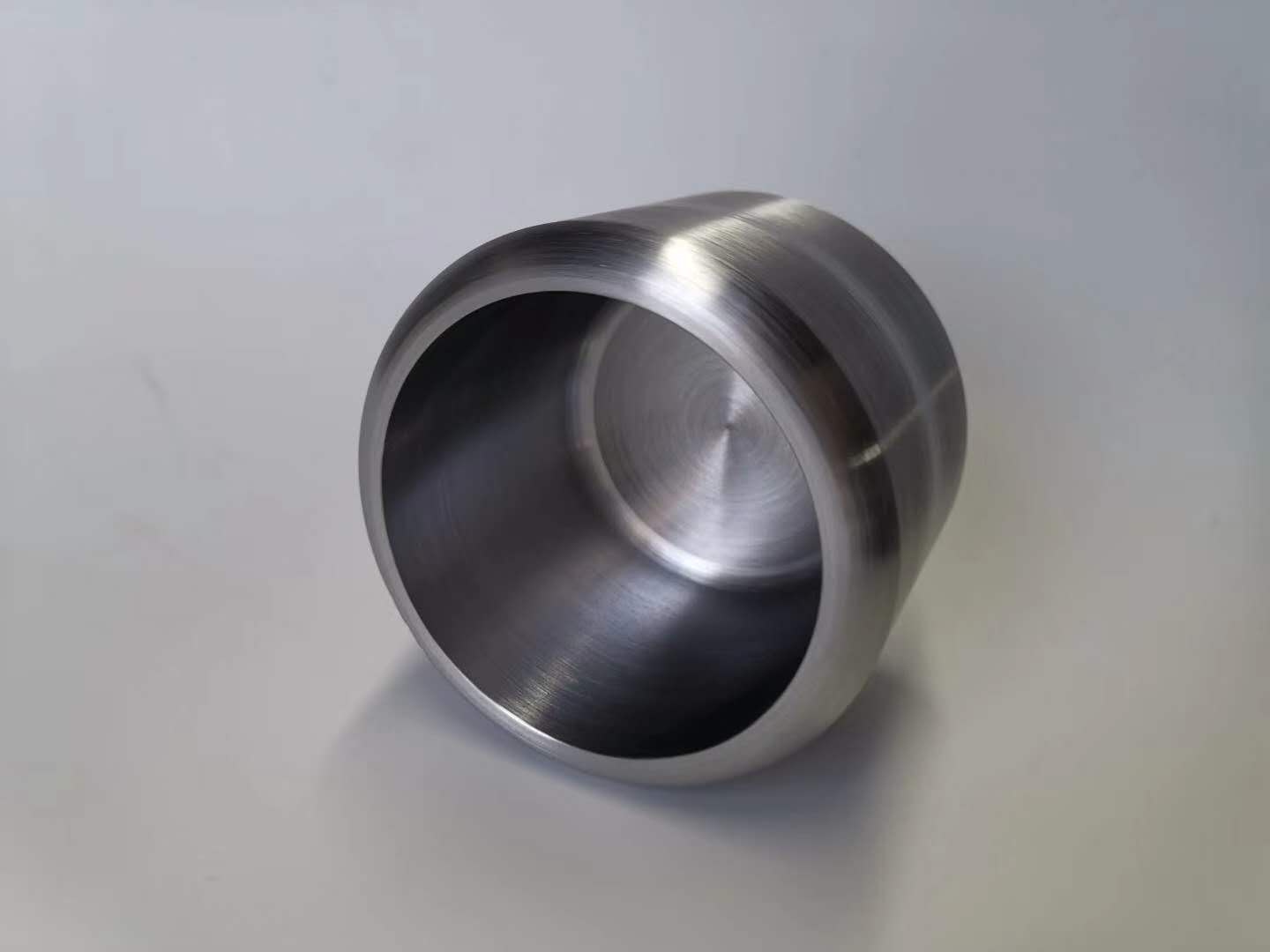

Tantalum is a kind of filamentous tantalum material made of tantalum powder by rolling, drawing and other plastic processing methods.

Manufacturing process:

Powder metallurgy

The technological process is as follows: raw material (tantalum powder)→ mixing → forming → vertical melting → rotary forging → intermediate annealing → drawing → finished annealing → quality inspection → packaging and warehousing.

Smelting method

The technological process is as follows: raw material (tantalum powder)→ mixing → presintering → electron beam melting → fine forging → intermediate annealing → rotary forging → intermediate annealing → drawing → finished annealing → quality inspection → packaging and warehousing.

It can be classified according to its chemical purity and properties:

According to chemical purity, it can be divided into three categories :(1) metallurgical tantalum wire with purity of 99.0%Ta; (2) High purity tantalum wire with purity of 99.0% ~ 99.9%Ta; (3) Ultra-high purity tantalum wire with purity of 99.9% ~ 99.99%Ta.

It can be divided into 4 categories according to its properties :(1) chemical corrosion-resistant tantalum wire; (2) High-temperature and high-strength tantalum wire; (3) Antioxidant tantalum embrittlement wire; (4) Tantalum capacitors.

Product attributes:

Grades: Ta1, Ta2, TaW2.5, TaW7.5, TaW10, TaNb3, TaNb20, TaNb40, etc.

Standard: GB/T3463-1995; Purity: Pure tantalum > 99.95%; State: annealed (M) or hard (Y);

Size: dish silk: Φ 0.6 ~ 5 mm straight wire: Φ Φ 1 ~ 3 * Φ L2m (Max)

Diameter and tolerance:

USES:

Tantalum wire is the most used in the electronic industry, mainly used in the anode lead of tantalum electrolytic capacitor. The high oxygen resistant brittle tantalum wire can also be used to make tantalum foil capacitors, which can be used in potassium dichromate and sulfuric acid capacitances at 772 ℃ (100℃) and extra-high flash voltage (350V). In addition, tantalum wire can also be used as vacuum electron cathode emitter, ion sputtering and spraying materials.