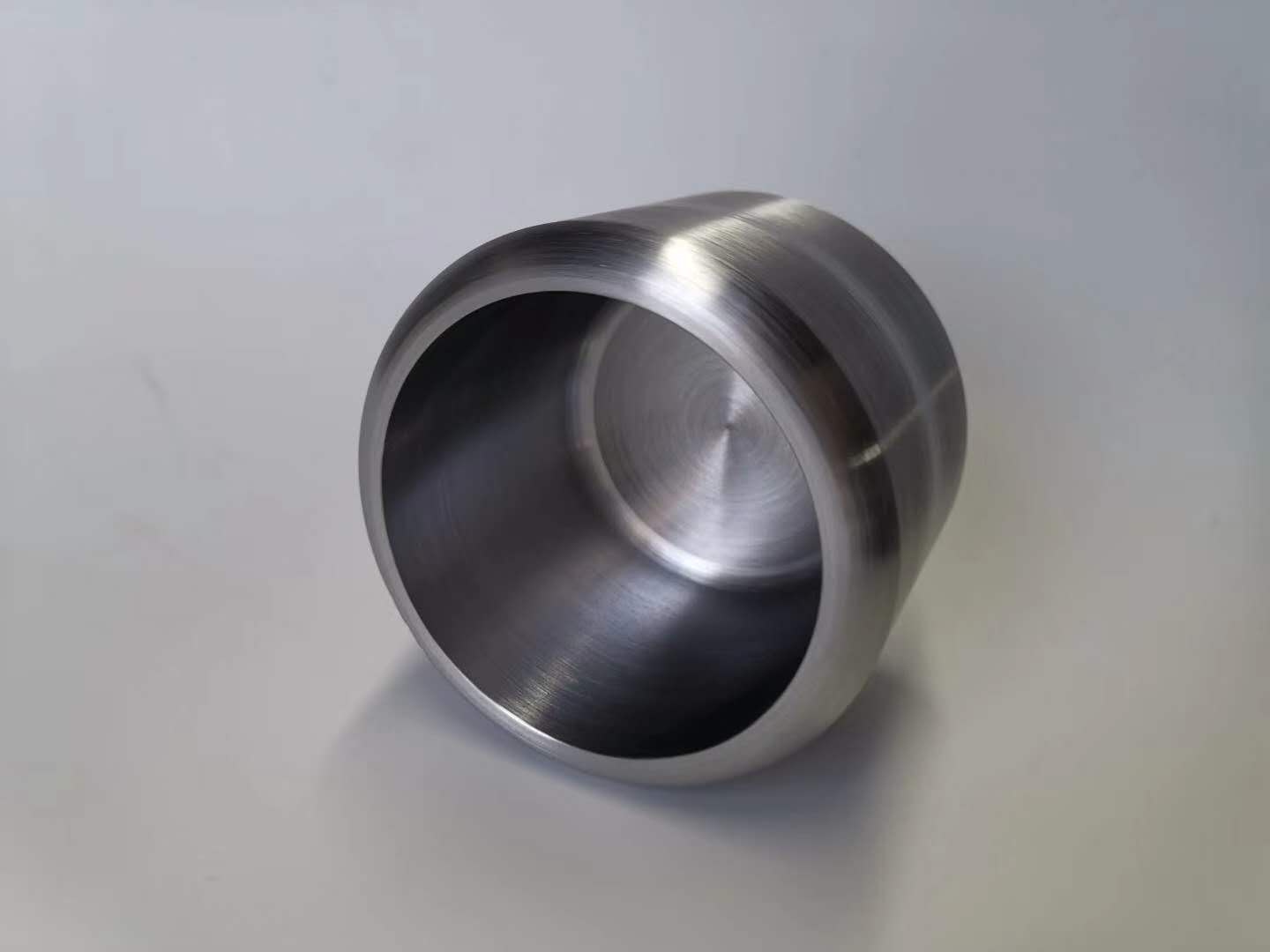

Properties and applications of tungsten crucible

Tungsten Crucible (English name: Tungsten Crucibles) is one of metal products, mainly divided into sintered forming (applied to powder metallurgy technology), stamping forming and spinning forming. Tungsten bar turning and forming (general size is relatively small), welding forming a variety of pure tungsten plate, tungsten slice and pure tungsten bar through the corresponding process. The tungsten crucible can be used in a vacuum inert gas below 2600 degrees. Tungsten melting point boiling point, high temperature strength, abrasion resistance and corrosion resistance, heat conductivity, small thermal expansion coefficient, good hardenability.

Physical and chemical properties:

1. Purity: W≥99.95%;

2. Density: ≥18.5g/cm3;

3. Maximum application temperature environment: 2400℃.

Production process:

Tungsten powder -- sieving -- batch -- isostatic pressing -- rough car processing -- intermediate frequency sintering -- fine car processing -- packaging.

USES:

Because the melting point of tungsten is as high as 3410℃, tungsten crucible is widely used in sapphire single crystal growth furnace, quartz glass melting furnace, rare earth smelting furnace and other core containers in the industrial furnace, and its working temperature environment is generally above 2000℃.

Especially for sapphire single crystal growth furnace, the tungsten crucible with the characteristics of high purity, high density, no internal crack, precise size, smooth inside and outside wall, etc. plays a key role in the success rate of seed crystal, quality control of crystal drawing, decrystallization and service life of sapphire crystal growth process.